Ingen varer

Priserne er inklusiv moms

Varen er nu lagt i din kurv

Der er 0 varer i din kurv Der er 1 vare i din kurv

Ikke på lager

25079

Skriv din e-mail-adresse her, hvis du vil have besked når vi igen har denne vare på lager:

Jeg ønsker en e-mail når varen kommer på lager

PLACTIVE AN1™ is an innovative Nanocomposite developed with a high quality PLA and a patented, scientifically validated and highly effective Nano-Copper additive. This unique combination of technologies brings the following characteristics to our products:

Antibacterial action has been scientifically validated eliminating more than 99.99% of fungi, viruses, bacteria and a wide range of microorganisms.

Antibacterial properties confirmed by two microbiology laboratories in Chile and USA.

PLACTIVE™ is a FDA Registered Material and EU compliant (No. 10/2011, No. 1935/2004 and No. 2023/2006).

The manufacturer also has certification ISO 9001/2015 and is REACH compliant.

It has thermoforming characteristics that facilitates post-processing and final adjustments of the 3D printed application.

Clinically tested in prosthesis for amputees with excellent results. Ideal for the manufacture of other medical applications where it’s dangerous to have bacterial contamination, such as postoperative prostheses, wound dressing and surgical equipment

The Nano-Additive mantains all the mechanical properties of the material.

PLACTIVE is currently being tested by NASA to evaluate its impact on interplanetary microbial contamination.

Non-toxic product and environmentally friendly (biodegradable).

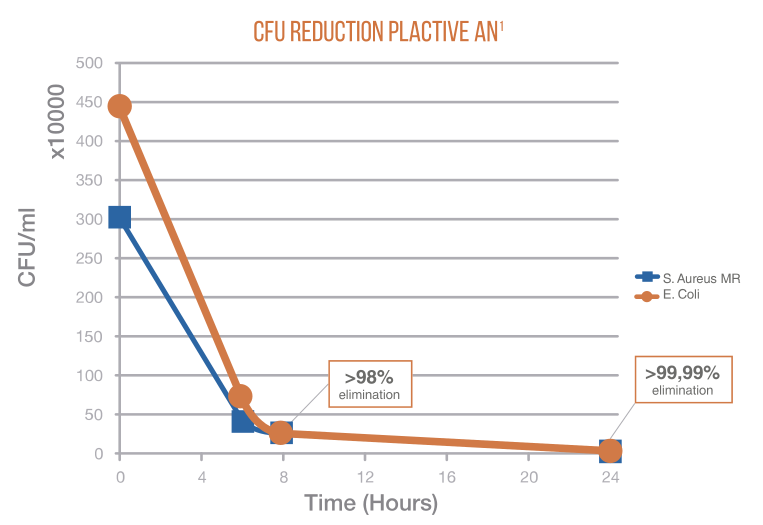

PLACTIVE ™ ANTIBACTERIAL ACTIVITY

This graphic shows the results of 2 studies conducted by microbiology laboratories in USA and Chile1,2. Both studies confirm that the Colony Forming Units (CFU) of Staphylococcus aureus MRSA and Escherichia coli DH5α, falls abruptly during the first 6 hours of exposure to PLACTIVE (>95%), continuing the elimination of bacterial strains until reaching >98% elimination at 8 hours and >99.99% elimination at 24 hours.

1. SITU Biosciences Microbiology Laboratory, USA.

2. Microbiology Laboratory of Universidad Católica de Valparaíso, Chile.

| Mærke | Copper3D |

| Materiale | PLA |

| Diameter | 1.75mm |

| Farve | Grøn |

| Vægt | 750g |

| Print temperatur | 190°C - 210°C |

| Opvarmet seng krævet | Nej |

| Anbefalet temperatur på seng | 0°C - 60°C |

| Lager | Online |

3D PRINTER CONFIGURATION PARAMETERS WITH PLACTIVE ™

| PRINTING TEMP. | 190 - 210 °C |

| PRINTING SPEED | 40 - 50 MM/SEG |

| LAYER HEIGHT | ≥ 0.1 MM |

| PRINT BED TEMP. | ± 0 - 60 °C |

MATERIAL PROPERTIES OF PLACTIVE ™

| Physical Properties | PLACTIVE ™ | ASIM Method |

| Specific Gravity, g/cc | 1.24 | D792 |

| MFR, g/10 min(2) | 6 | D1238 |

| Relative Viscosity(3) | 4.0 | D5225 |

| Clarity | Transparent | |

| Peak Melt Temperature, °C | 145-160 | D3418 |

| Glass Transition Temperature, °C | 55-60 | D3418 |

| Mechanical Property | ||

| Tensile Yield Strength, psi (MPa) | 8700 (60) | D882 |

| Tensile Strength at Break, psi (MPa) | 7700 (53) | D882 |

| Tensile Modulus, psi (MPa) | 524,000 (3.6) | D882 |

| Tensile Elongation, % | 6 | D882 |

| Notched Izod Impact, ft-lb/in (J/m) | 0.3 (16) | D256 |

| Flexural Strength, psi (MPa) | 12,000 (83) | D790 |

| Flexural Modulus, psi (MPa) | 555,000 (3.8) | D790 |

| Heat Distortion Temperature, °C 66 psi (0.45 MPa) |

55 | E2092 |

“Keep the package sealed until ready to use and promptly reseal any unused material”

(1) Typical properties for injection molded amorphous bars; not to be construed as specifications.

(2) 210 °C/2. 16kg

(3) RV measured at 1.0 g/dL in chicroform at 30°C

*values can vary by +/- 5% due to environmental conditions