Ingen varer

Priserne er inklusiv moms

Varen er nu lagt i din kurv

Der er 0 varer i din kurv Der er 1 vare i din kurv

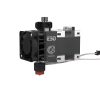

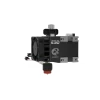

Revo Hemera er et kompakt, kraftfuldt ekstruderingssystem med bekvemmeligheden fra E3Ds RapidChange Revo-økosystem. Med dobbeltdrevne gear og hærdet stålkogeplader til at gribe glødetråden fra begge sider, giver Revo Hemera din 3D-printer enestående skubbekraft. En stramt afgrænset filamentbane betyder, at materialet ikke kan bøje sig og bøje sig på vej til smeltezonen, hvilket gør det til et topvalg til udfordrende 3D-printfilamenter, som f.eks.

- Kompatibel med Revo-dyser, så du kan skifte dyser ved stuetemperatur med kun fingrene

- Brugerdefinerede motorendestykker giver praktiske T-slidser til flad montering, hvilket giver masser af plads til andet tilbehør, som f.eks. sengenivelleringsprober eller delkøleventilatorer

- Kompatibel med mange populære 3D-printere, inklusive Creality CR-serien og Ender-serien, Prusa, Anet, Biqu, Monoprice og mange flere. Se vores 3D-printeropgraderingsvejledninger

- Alt hvad du behøver er at komme i gang er inkluderet i æsken - bare monter den på din 3D-printer og start 3D-print

På Fjernlager

27701

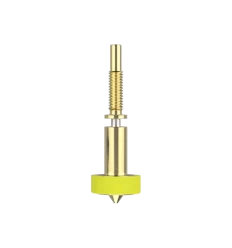

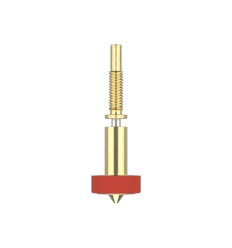

Ready for Revo. Change nozzles at room temperature using just your fingers. No complex tools, no hot tightening. Revo Nozzles are a factory sealed nozzle and heatbreak in one, so they’re easy to fit and can’t leak material when in use.

New hotness. A Revo HeaterCore heats up in seconds. It’s much safer too – unlike other solutions on the market, a positive temperature coefficient (PTC) means the Revo HeaterCore can not melt at extreme temperatures: power reduces as it gets hotter, so hazards are reduced in the event of a thermal runaway.

Tight filament path. Hemera is a combined extruder and HotEnd, so it has fewer transitions than most extrusion systems available. A tight filament path gives it excellent performance with hard-to-print materials, like flexibles. Even with the softest flexibles, you can print without the underextrusion or filament binding you would get with a typical setup.

Resistant to wear. Hemera’s stainless steel hobb teeth are resistant to wear, so with the right combination of components, your Hemera can effortlessly 3D print advanced abrasive and composite materials, like carbon fibre-filled filaments, for serious industrial applications.

(Disclaimer: abrasion resistant Revo Nozzle required – ETA 2022)

Optimised airflow. Hemera has a uniquely designed lightweight aluminium heatsink for highly effective cooling. Air is circulated through the fins and then up and away from the 3D print, preventing any unintentional warping of the printed part.

No loss of torque. Hemera’s 3.32:1 dual drive gears produce pushing force of up to 120N on your filament from both sides, for accurate, controlled extrusion with no loss of torque. Sharp, individually machined hobb teeth ensure excellent filament grip strength, and round-bottomed profiles help to reduce any build-up of filament debris, for high-quality, consistent extrusion from first to final layer.

E3D quality. Each Hemera drivetrain includes shielded bearings and high quality igus® bushings for optimal wear resistance. Lubrication is precisely applied to each drivetrain by robots during assembly, and drivetrains are thoroughly analysed using an accelerated wear test to ensure your Hemera will have many years of 3D printing life.

Mounting options. Hemera’s custom motor end-caps provide convenient T-slots for flat mounting on many popular 3D printers, leaving plenty of room left for other accessories, like bed levelling probes, or extra part cooling fans.

Flexible to any setup. Hemera plays nice with Bowden and direct drive setups. Just add a Bowden adaptor (sold separately) and your Hemera becomes a powerful Bowden filament drive.

Please note:

- This sink retains full compatibility with the Hemera HeatBreak, V6, Volcano, and SuperVolcano HeaterBlocks.

- You may need to adjust your Z offset when changing nozzles.

Key features:

- Compatible with 1.75mm filament

- Max temp: 300C

- Direct drive

- Up to 120N pushing force

- Top choice for flexible filaments

- T-slot mounting system

- Step angle: 1.8°

- Rated current: 1.33A

- 3.32:1 gear ratio

Kit includes:

- 1 x Hemera Assembly

- 1 x Hemera fixings kit

- 1 x 40 x 40 x 10 mm 12V or 24V Fan

- 1 x Revo HeaterCore 12V or 24V

- 1 x Revo HeaterCore spring

- 1 x Extension cable kit

Single nozzle kit:

- 1 x 0.40 Brass Revo Nozzle

Fully loaded nozzle kit:

- 1 x 0.25, 0.40, 0.60 & 0.80 Brass Revo Nozzles

Documentation: