Ingen varer

Priserne er inklusiv moms

Varen er nu lagt i din kurv

Der er 0 varer i din kurv Der er 1 vare i din kurv

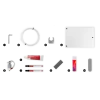

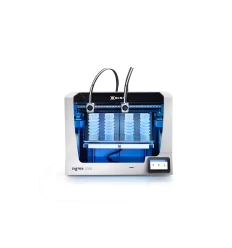

Vedligeholdelsessættet til Sigmax indeholder de mest anvendte dele til vedligeholdelse eller udskiftning af printeren. Vedligeholdelsesarbejde skal gøres regelmæssigt for at holde printeren i god stand og til enhver tid opnå udskrifter af høj kvalitet. Før du foretager reparationer, er det vigtigt at slukke printeren og lade den køle ned.

Ikke på lager

25102

Skriv din e-mail-adresse her, hvis du vil have besked når vi igen har denne vare på lager:

Jeg ønsker en e-mail når varen kommer på lager

Maintenance operations that can be done with the kit:

Lubricate and clean axes:

Periodically, according to the Maintenance Alerts via LCD screen, it is recommended to clean and grease the axes of the Sigmax with the lubrication kit to ensure a smooth and precise performance of its mechanical components. In the following manual you will find a detailed step by step guide on how to lubricate and clean the axes of your printer

Clean the hotend:

To ensure an optimal printed parts, it is important to maintain the hotends correctly. Maintenance of the inside of the hotend should be performed once every month, every time you switch materials or if the nozzle is clogged. In the following manual you will find a detailed step by step guide on how to clean the hotend of your printer

Installing shims:

Shims are elements that mechanically correct the Z offset when printing in Mirror or Duplication mode. In these modes both toolheads work simultaneously, so it is key important to make sure both nozzle tips are exactly at the same height. In the following manual you will find a detailed step by step guide on how to install the shims on your printer

Change the hotend:

The maintenance kit includes 2 0,4mm e3D hotends. It is recommended to install a new hotend when you do not get a clean hotend when performing the “Nylon Cleaning Method” described on the “Clean the hotend” process. In the following manual you will find a detailed step by step guide on how to install a hotend on your printer

What’s in the box:

4x Allen key (1)

· Nylon cleaning filament (2)

· Set of shims (3)

· Glass printing surface (4)

· x2 0.4mm Hotend by e3D (5)

· Grease 50ml (6)

· Solvent 12ml and Lubrication Oil 12ml (7)

· x4 Purger cloths (8)

· Magigoo: Build plate adhesive (9)

· Calibration gauge (10)